© 2024 Penico Engineering Pty Ltd. All rights reserved

- Site by:

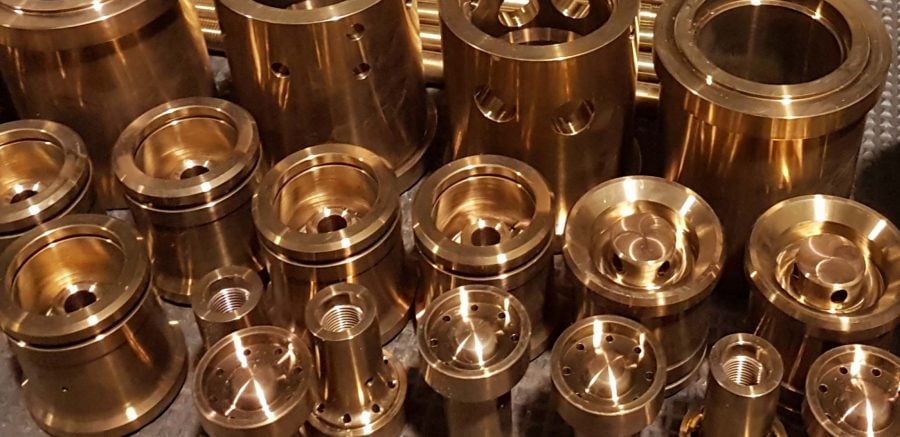

Penico Engineering was founded by Bob Jones in 1986 when operations commenced in a small workshop in Wickham, Newcastle. The business has since expanded into a much larger premises and the plant and equipment is continually updated to meet the changing landscape of manufacturing.

The quality of our company’s products is the concern of every person in the organisation. Quality starts with the receipt of an inquiry, through the quotation stage, receipt of order and right through to delivery of the product to the customer.

The Quality Management System operating at our company ensures that customers receive products that meet their specified requirements in terms of accuracy, economy and delivery .

Penico writes and checks all of our CNC Programs OFFLINE. This allows our CNC machines to keep running whilst components are being programmed saving the customer valuable lead-time and enabling Penico to maximise our plants capacity. Every aspect of our production is computerised allowing us to plan, procure, control and review all aspects of a project at all times. This aids an efficient, accurate and concise manufacturing process with full traceability and accountability.